Project Focus: Egger

EGGER is Northumberland’s largest manufacturing employer. The EGGER factory in Hexham manufactures chipboard of various grades from timber. As the company, which commissioned its first chipboard plant in 1961 in St. Johann (Austria), now operates 22 production locations in 11 countries, foreign language skills are considered key to efficient collaboration and the exchange of knowledge and expertise between the different plants.

4 Translations provides language training in group-settings for staff working at Egger’s chipboard manufacturing sites in Hexham and Auchinleck, as well as highly customised, on-site 1:1 English courses for engineers from Egger plants in Austria and France. Some participants already benefited from Egger's foreign language courses provided at their plant e.g. in St. Johann, and we have also been able to cooperate with their tutor.

In addition to language training, 4 Translations provides interpreting services at video conferences with Egger management in St. Johann and other members of the European EGGER Forum. These conferences have a set format and agenda, and copies of slide presentations are available well in advance so that the interpreter can go into these conferences well prepared. Interpreters have to be prepared for the unexpected, though. Unexpected topics may come up ad-hoc in a meeting, and the contents of discussions during maintenance or repair work on the shop floor is not predictable – the only preparation the interpreter can do concerns general terminology.

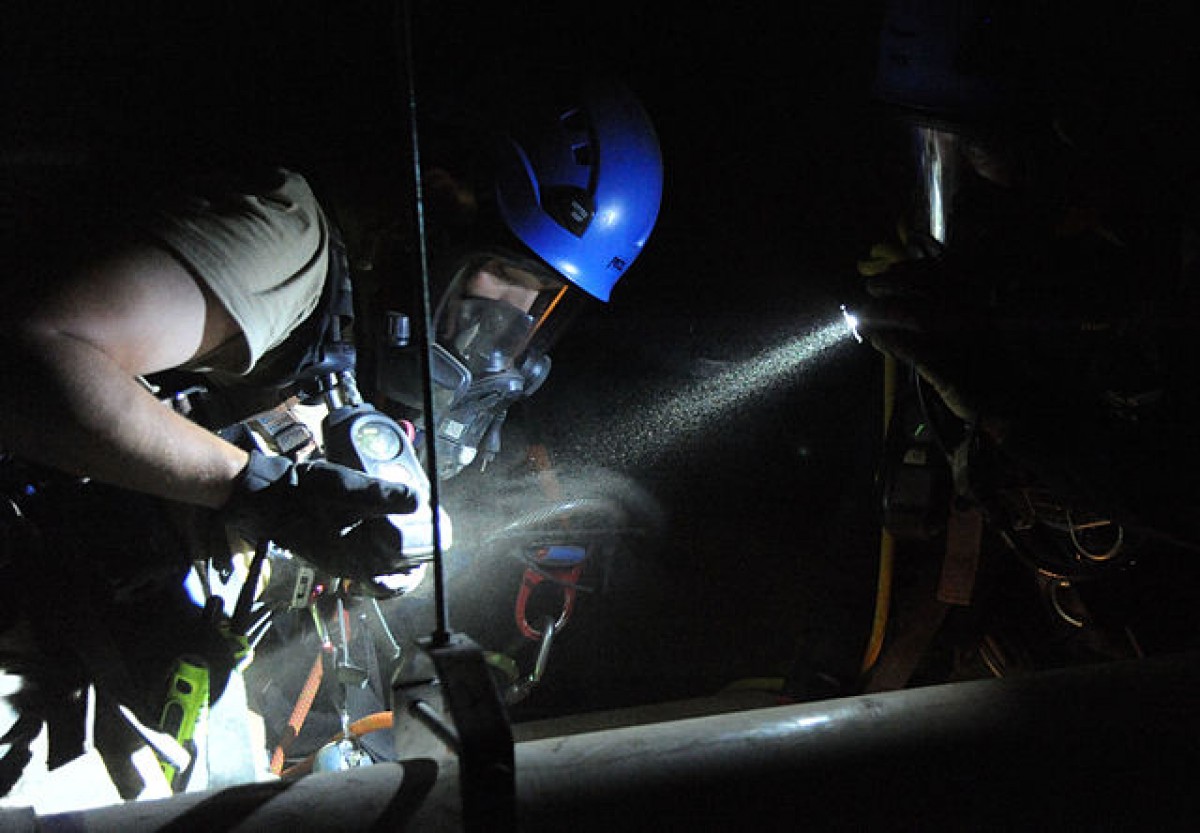

One particular interpreting assignment surprisingly presented a height rather than terminology challenge: A special team had flown in from Vienna for the annual clean-up of the "Wesp" (wet electrostatic precipitator) unit in the Hexham plant and had to complete a Health and Safety course at Newcastle International Airport Training Academy first. The one-day course included a practical exercise in a disused tower to simulate risks when working in confined spaces, and required wearing a breathing apparatus as well as a safety harness to get down safely from the top of the tower using the narrow and dark internal staircase, i.e. a confined space. The interpreter was at hand to explain the PSE – at the top of the tower – but, luckily, was then asked to use the external staircase to get down and observe the actual exercise from ground level. A few years later, the team had to do the same course again with Total Safety®, a provider of integrated safety strategies and solutions for hazardous environments, but on Egger's premises in Hexham. The practical exercise was done on Total Safety's specialised unit for confined space training, and the height of 5m was easily managed. The instructions for working in confined spaces were "translated" by the instructor into a sequence of actions and movements which the team needs to execute automatically, i.e. they have to become second nature when working in such environments. While interpreters use words to translate and explain, hand signals and practical drills are highly effective for imprinting movements into body memory.

Health, Safety and Environment is an important priority in every business. The EGGER Group sees active climate protection as a duty and commits to Net Zero by 2050.

For the latest Egger news, do visit Egger's Facebook page.

Egger production plant in Hexham.

Egger production plant in Hexham.

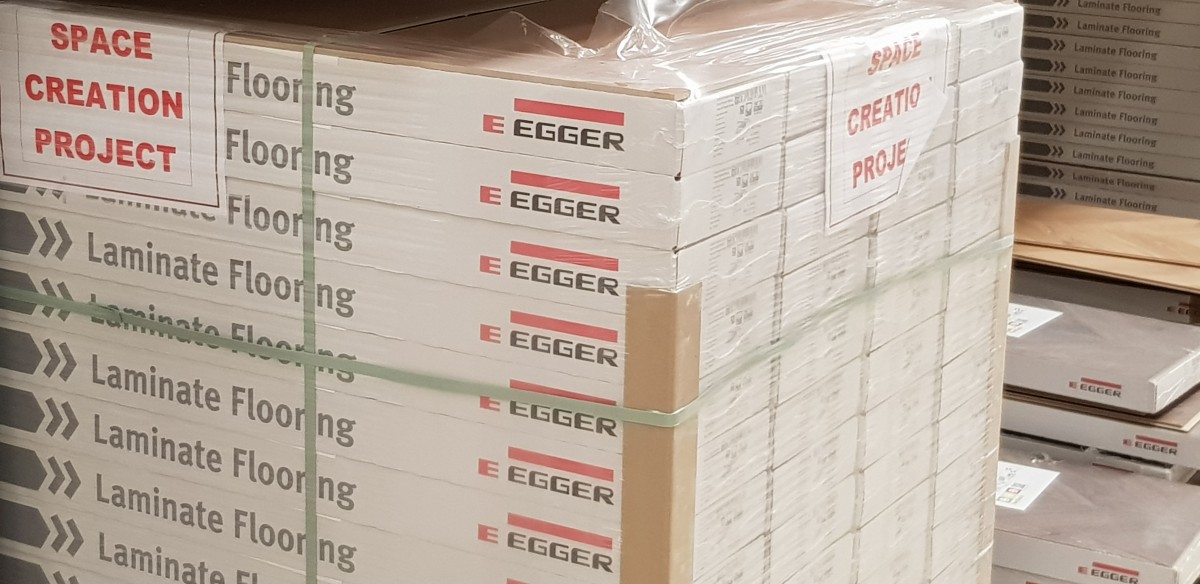

Egger flooring product for purchase at B&Q. EGGER is a full-range supplier for furniture and interior design, for wood construction and for wood-based flooring, making it a reliable partner for the furniture industry, wood and flooring retailers and DIY stores.

Egger flooring product for purchase at B&Q. EGGER is a full-range supplier for furniture and interior design, for wood construction and for wood-based flooring, making it a reliable partner for the furniture industry, wood and flooring retailers and DIY stores.

Checking the atmosphere in a confined space. 20.8% is the normal percentage of oxygen in the atmosphere. The gas monitor will give out an alarm for oxygen deficiency at 19%. (Photo: Wikimedia Commons)

Checking the atmosphere in a confined space. 20.8% is the normal percentage of oxygen in the atmosphere. The gas monitor will give out an alarm for oxygen deficiency at 19%. (Photo: Wikimedia Commons)

From the Blog

-

Hands-on

Hands-on work experience at 4Translations gives Annabel valuable insights into industry and a taste for (much!) more

-

Northumberland National Park – Now & Forever

Voice-first translations for Northumberland National Park Authority.

-

Legal work

Last wills, witness statements, applications of return in child abduction cases, summonses in Court of Session actions.

-

Learning Poverty

53 percent of children in low- and middle-income countries cannot read and understand a simple story by the end of primary school. In poor countries, the level is as high as 80 percent. Professor Thurston and Dr Maria Cockerill at Queen's University Belfast focus on cooperative/peer learning and find cost-effective solutions which improve learning outcomes.